by Frank Dixon | May 5, 2024 | Commercial roofing

If you’re facing the task of choosing a durable, cost-effective material for your roof, an EPDM roof might be your answer. This concise guide evaluates EPDM roofing systems, highlighting their performance and installation costs. Get help making an informed decision through these insights tailored to property owners and professionals alike.

Inside this blog:

- The Benefits of EPDM Roofing Systems

- Installation Methods and Considerations

- EPDM Roof Maintenance and Repair Tips

The Benefits of EPDM Roofing Systems

EPDM roofing systems, a popular choice among commercial roofing systems, are known for their durability, offering resistance to ultraviolet radiation and even having the option to add an AFR layer for enhanced fire resistance. High-quality EPDM coatings contribute to the long lifespan of these roofs by providing additional protection against environmental elements.

But what sets EPDM apart is not just its durability, but also its cost-effectiveness and versatility.

1. Durability and Longevity

EPDM roofing has been enhanced with new manufacturing formulas to improve its resistance to radiation and UV rays, contributing to its longevity. It can withstand extreme temperatures, ranging from -40o F to 300o F, without damage. The chemically saturated molecular structure of EPDM provides high resistance to weather elements such as wind and hail, further enhancing its durability. A well-installed EPDM roofing system can have a lifespan of around 20 years, and with proper maintenance, it can potentially last between 30 and 50 years.

2. Cost-Effectiveness

EPDM roofing is cost-effective, with installation costs typically lower than those for TPO and PVC alternatives. Costs for EPDM roofing average $12.00-$17.00 per square foot, with additional installation materials ranging from $350 to $450. Also, EPDM maintenance costs are typically low, though ballasted systems may incur higher expenses throughout their lifespan.

Thicker EPDM membranes enhance roof life and can lead to reduced heating and cooling costs, contributing to long-term savings.

3. Versatility and Adaptability

The versatility of EPDM roofing is reflected in its availability in various thicknesses to meet the needs of different buildings and climates. For residential roofs in milder climates and low-slope, small commercial buildings with minimal exposure to harsh weather, a 45 mil thick EPDM membrane is often suitable. In environments with moderate weather conditions, EPDM membranes with a thickness of 1.14mm provide a well-balanced option in terms of cost and performance.

Installation Methods and Considerations

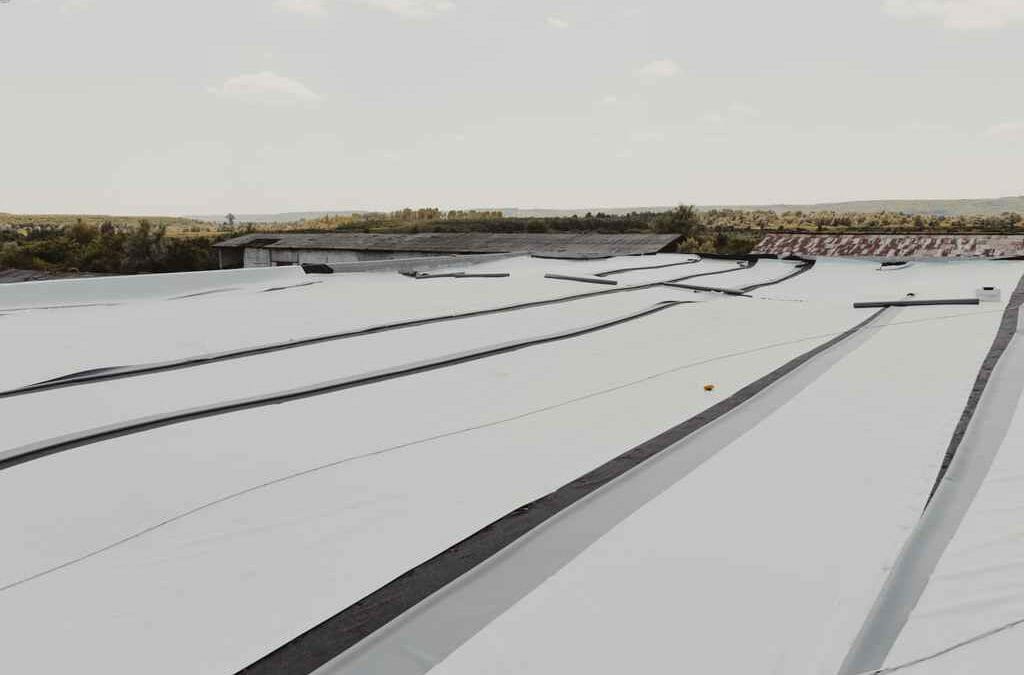

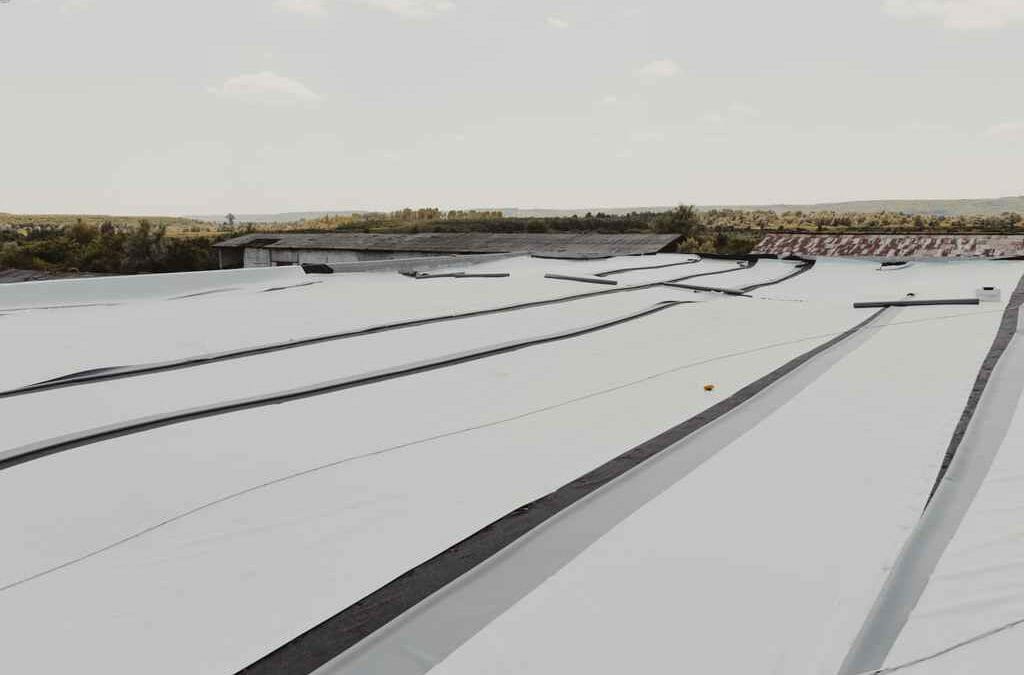

Installation plays a crucial role in the performance and longevity of EPDM roofing systems. These systems are installed using three main techniques: mechanically fastened, adhered, or ballasted, each with its own advantages and considerations. The ballasted installation involves loose-laying the roof over insulation and holding it in place with pavers or smooth stones.

EPDM roofing is generally not advised for high-pitched roofs due to lower durability and increased vulnerability to weather impacts. For pitched roof applications, EPDM is appropriate for low to moderate roof pitch, with the effectiveness contingent on the pitch angle’s impact on water drainage. Hiring professional installers for EPDM roofing ensures the proper application and maximizes the lifespan of the roof.

Mechanically Fastened

During a mechanically fastened installation of EPDM roofing, the membrane is laid out across the roof in a specific manner to ensure proper overhang at perimeter edges and upstands for trimming. The installation then proceeds from the roof’s center towards the edges, folding the membrane inward to access and secure the RUSS. Securing the EPDM roofing involves the application of adhesive to the RUSS and waiting until it becomes tacky, then pressing it together with the membrane, proceeding piece by piece.

Fully Adhered

The fully adhered installation method for EPDM roofing involves gluing the membrane directly to the insulation layer using a bonding adhesive. Prior to applying splice adhesive, it’s imperative to clean the RUSS (Reinforced Universal Secure Strip) and the underside of the EPDM membrane with splice wash to ensure proper adhesion.

Ballasted

The EPDM membrane is laid loosely over the flat roof system substrate in a ballasted installation, making it suitable for flat roofs. It is then held in place with materials like smooth stones or concrete pavers. Ballasted systems enhance the protection of EPDM membranes against ultraviolet light, tree branches, and hail, and can improve energy efficiency when coupled with reflective coatings or paired with polyiso insulation.

EPDM Roof Maintenance and Repair Tips

Regular maintenance and inspection are essential for maintaining the condition and longevity of EPDM roofs. Scheduled maintenance is essential to prevent problems and ensure prompt repairs. Inspections are particularly important after severe weather or service work on rooftop equipment to identify any potential issues. Trimming back overhanging branches can help prevent damage to the EPDM roofing, safeguarding against potential abrasions or punctures.

Regular Inspections

Conducting regular inspections of EPDM roofs is necessary to identify potential issues before they escalate. It’s recommended to inspect an EPDM roof at least twice a year to detect any damage requiring repairs.

Cleaning and Debris Removal

Frequent removal of debris such as leaves and dirt from the EPDM roof is necessary to maintain its condition and prevent potential damage.

Roof coatings create a flexible, seamless barrier that is UV-resistant and watertight, which aids in protecting the EPDM roof from weather elements, thereby extending its lifespan.

Repair Techniques

Roofs made of EPDM can sustain abrupt damage from hail impacts, wind-driven debris, and foot traffic on the rooftop. This can lead to the need for repairs or replacements. Elastomeric coatings on aged EPDM roofs can improve performance and increase reflectivity. Shrinkage is a common issue for EPDM roofs, often necessitating repair to address membrane separation around edges and penetrations.

Solvent-based roof coatings, such as silicone and urethane, are effective for repairing EPDM roofing.

Understanding EPDM Roofing

EPDM roofing offers a durable, cost-effective, and versatile roofing solution for both commercial and residential applications. With the ability to withstand extreme weather conditions and its low installation and maintenance costs, EPDM roofing proves to be a reliable choice.

At Alamo Roofing, we can provide reliable roofing services. When your roof needs a pick-me-up, our skilled team can get the job done. Reach out to us for a free estimate!

by Frank Dixon | Apr 27, 2024 | Commercial roofing, Roof Repair, Roof Repairs in Naperville Illinois

Facing issues with your rubber roof? This article cuts through the complexities to offer you precise rubber roof repair techniques. Learn to identify symptoms, gather the essential tools, and apply the correct sealants for a durable fix. With comprehensive steps and expert insights, we’ll guide you through the process to ensure your roof remains robust and leak-free.

Inside this blog:

- Understanding Rubber Roofing Systems

- Identifying Common Rubber Roof Problems

- Step-by-Step Guide to Repairing a Rubber Roof

Understanding Rubber Roofing Systems

A key player in the roofing industry, especially when it comes to RVs, is the rubber roof. Characterized by its light weight and adaptability, rubber roofing has carved a niche for itself. But what exactly is a rubber roof, and how does it stand out from its counterparts?

A rubber roof isn’t just a monolithic entity. Rather, it’s a term that covers a variety of roofing systems, each with their own unique characteristics and benefits. Some common types of rubber roofing systems include:

- EPDM roof: known for its longevity and resistance to harsh weather

- Liquid rubber: used as a protective coating

- TPO roof: offers excellent energy efficiency and durability

- PVC roof: known for its strength and resistance to chemicals

These roofing systems, including flat roofs, offer a versatile solution for addressing diverse roofing needs.

The Benefits of Rubber Roofing

So, why should you consider rubber roofing for your RV or any other application? Well, the answer lies in the plethora of benefits that these roofing systems offer.

Rubber roofs are highly valued for their longevity, with potential lifespans exceeding 40 years. They are adaptable, effortlessly conforming to the shape and structural changes of a building over time, ensuring a consistent and reliable barrier against environmental elements. Additionally, rubber roofs offer substantial resistance to:

They are also low maintenance, requiring just semi-annual inspections, and their lightweight nature contributes to reduced installation, transportation, and long-term repair costs. Last but not least, rubber roofs have energy-efficient properties that include blocking solar heat to reduce cooling costs and providing good insulation to lower heating expenses.

Identifying Common Rubber Roof Problems

Like any other roofing system, rubber roofs are not without their share of issues. While they are designed to withstand harsh weather conditions and other environmental factors, they can still suffer from problems such as leaks, tears, or punctures. These issues can compromise the functionality and lifespan of the roof if not addressed promptly.

RVs, in particular, face additional challenges. The rubber roofs on RVs can suffer from seam separation and cracks due to debris build-up leading to water pooling. Leaks can originate from the roof’s exterior and interior components, like water heaters and potable water fills. Therefore, prompt repair of cracks and leaks is crucial in preventing serious structural damage to the interior and exterior of the RV.

Step-by-Step Guide to Repairing a Rubber Roof

Armed with the right tools and materials, it’s time to dive into the actual repair process. Here, we present a comprehensive step-by-step guide that will walk you through the entire process, from locating the leak to sealing the edges of the repair. The process of repairing a leak on a rubber roof involves several steps:

1. Locating the Leak

Locating a leak on a rubber roof can be a tad tricky, but with the right approach, it can be done effectively. A pressure test is one technique that can help you detect leaks on a rubber roof by identifying differences in air pressure.

The procedure involves increasing the air pressure inside the RV and applying soapy water or a specialized liquid on the exterior. This method causes bubbles to form at the leak points when there’s a higher air pressure inside the RV than outside, allowing for accurate identification of where repairs are needed.

2. Preparing the Roof Surface

Once you’ve located the leak, the next step is to prepare the roof surface for repair. This is a critical stage as the effectiveness of the repair largely depends on how well the surface is prepared.

To clean the roof surface, you can use a rag or paper towels to apply rubbing alcohol, which can effectively remove contaminants. You should aim to cover the entire area where the patch will adhere to the rubber roof. Proper cleaning of the roof surface is essential for the successful application of a repair patch, ensuring the patch adheres securely to the roof.

3. Cutting and Applying the Patch

With the surface prepared, the next step is to cut and apply the patch. This is where your utility knife comes into play.

First, measure an area larger than the damaged spot by at least 2-3 inches on all sides to ensure full coverage with the rubber patch. Use a straight edge and a sharp utility knife to cut the rubber patch to the measured size. Then, spread the adhesive evenly over the underside of the rubber patch and on the prepared area of the roof where the patch will be placed.

Wait for the adhesive to become tacky before attaching the patch to the roof, as this ensures the best bond. Position the rubber patch correctly over the damaged area and press down firmly, starting from the center and moving outwards to remove any air bubbles.

4. Sealing the Edges

The final step in the repair process is to seal the edges of the patch. This step is vital, as it ensures a watertight seal over the repaired area, preventing any water intrusion that could cause more damage.

Before applying the new sealant, follow these steps:

- Completely remove any existing damaged sealant to ensure proper adhesion and sealing.

- Use a high-quality RV roof sealant that is compatible with the rubber membrane.

- Apply the sealant along the edges of the patch.

After sealing, it’s essential to examine the edges for any gaps or misses. Doing so guarantees a watertight seal over the repaired area.

Upgrade Your Roofing System

Navigating the world of rubber roofs can seem daunting at first, but with the right knowledge and tools at hand, it’s a task that’s quite manageable. From understanding the different types of rubber roofs to identifying common problems and how to repair them, this guide has walked you through everything you need to know about rubber roofs.

Thankfully, we can do more than provide a guide. Our team can upgrade your roof and ensure that it provides adequate protection. So, contact Alamo Roofing today!

by Frank Dixon | Apr 22, 2024 | Commercial Roof Repair, Commercial roofing

Are you looking to extend the life of your commercial roof and prevent expensive repairs? Effective commercial roof maintenance involves regular inspections, proper cleaning, and ensuring functional drainage systems. This article offers detailed strategies to help business owners preserve their rooftops, from leak detection to preventative measures. Dive in to discover how to protect your investment and secure the longevity of your commercial roof.

Inside this blog:

- The Significance of Commercial Roof Inspections

- Ensuring Drainage Systems Function Properly

- Proactive Leak Management and Repair

The Significance of Commercial Roof Inspections

Similar to the significance of regular health check-ups for our well-being, frequent commercial roof inspections play a key role in prolonging the roof’s lifespan and sustaining its performance. Frequent inspections guarantee the peak performance of your roof, thereby shielding your business from expensive repairs and potential interruptions in operations.

Professionals recommend conducting inspections twice a year, particularly in the spring and fall, to prepare for potential winter issues, and adjust for other factors, such as roof age and local weather patterns.

Seasonal Inspection Strategies

Scheduling inspections to coincide with the changing seasons can be a game-changer in roof maintenance. Spring inspections are instrumental in identifying damages inflicted by harsh winter conditions, whereas fall inspections gear up the roof for the approaching winter.

These seasonal inspections allow you to anticipate potential issues and address them before they escalate, ensuring your roof’s performance remains optimal year-round.

Post-Weather Event Check-ups

Mother Nature can be unkind to our structures, especially during extreme weather conditions such as windstorms, hurricanes, heavy rains, or hail. Conducting a thorough inspection of the commercial roof is crucial after these events. Regular inspections can help identify potential damage, particularly to roof flashings, which are typically made of aluminum or galvanized steel and prone to damage or looseness.

Carrying out these post-weather event check-ups effectively protects your business premises and guarantees your roof continues to deliver the protection intended for the site owner.

The Role of Cleanliness in Roof Maintenance

A clean roof is a happy roof, and a happy roof translates to an efficient commercial building. Periodic cleaning of your roof can inhibit the growth of mold and algae, both of which can jeopardize the roof’s integrity and functionality. Moreover, maintaining cleanliness helps avoid the accumulation of debris, which can clog gutters or ventilation systems, leading to water drainage issues and roof damage.

Effective Debris and Dirt Removal Techniques

Keeping your roof free from debris and dirt not only keeps it looking good, but also helps in maintaining its structural integrity. Using a leaf blower can efficiently clear lighter debris such as leaves and twigs off a roof. For tougher grime, power washing with appropriate pressure settings can be employed without causing damage to the roofing material.

Ensuring Drainage Systems Function Properly

Drainage, though often overlooked, plays a significant role in roof maintenance. Proper drainage is vital for roof longevity, as it:

- Prevents clogged gutters and drains

- Avoids ponding water

- Strengthens the roof structure

- Reduces the risk of leaks

Hence, it is of utmost importance to keep your gutters and drains clear and ensure their proper functioning to evade such issues.

Gutter and Downspout Maintenance

Gutters and downspouts, the unsung heroes of your roofing system, play a vital role in directing water away from your building’s foundation. Ensuring that they do not sag and that water is properly draining away from the building is crucial to avoid drainage issues. Blocked gutters can lead to water not being channeled correctly, resulting in roof leaks and potential water damage.

Hence, routine inspection and maintenance of these components are fundamental to safeguarding your roof’s lifespan.

Proactive Leak Management and Repair

Leaks, the bane of any roofing system, can cause serious damage if not promptly addressed. To identify leaks early, look for signs like moss and algae growth on the roof, accumulation of dirt and organic matter, and water spots on interior ceilings and walls, which all indicate potential moisture intrusion.

Prompt reporting of leaks is imperative for warranty compliance, as most manufacturers’ commercial roofing warranties necessitate immediate notification to retain the coverage’s validity.

Spotting Early Signs of Leaks

Spotting early signs of leaks is similar to a detective hunt. Early signs of roof leaks may include observable and smelly indicators, such as:

- Dripping water

- Musty odors

- Water stains on ceilings and interior walls

- Bulging wall patches

- Spots on exterior walls

- Visible damage to roof materials like missing or warped shingles

To ensure the safety and longevity of your property, it’s crucial to conduct inspections regularly. These regular inspections can help you spot early signs of potential issues and take appropriate action to prevent further damage and avoid costly repairs.

Quick Response to Identified Leaks

Immediate action is the best response to identified leaks. It’s critical to respond to leaks immediately after detection to mitigate the risk of damage spreading. Fast leak repairs can prevent structural degradation of the roofing materials, maintaining the roof’s overall effectiveness.

Prompt action not only safeguards the interior of your building from water damage caused by standing water but also guarantees the safety of its occupants.

Contacting The Right Roofing Professionals

Just as you wouldn’t entrust your health to an unqualified doctor, entrusting your commercial roof to unqualified professionals is equally risky. When choosing a roofing contractor, it’s essential to verify proper licensing and roofing certificates.

Also, assessing the experience of a roofing contractor is important, including requesting referrals and reviews from past clients, especially those with similar roofs to your commercial property.

Contact Us for Commercial Roof Maintenance

Commercial roof maintenance is not a one-time task, but an ongoing commitment. It also involves choosing the right roofing professionals and long-term maintenance planning. By following these practices, you can extend your commercial roof’s lifespan and maintain its performance.

We can also help. At Alamo Roofing, we provide efficient roofing services. Our team specializes in maintenance, replacement, and more. Don’t hesitate to contact us!

by Frank Dixon | Jan 9, 2024 | Commercial roofing

Regarding your commercial space, the roof is one of the most critical elements, acting as the first line of defense against the elements and contributing significantly to the building’s energy efficiency.

Whether you’re dealing with aging materials or damage from a storm, knowing when and how to proceed with a roof replacement can be essential.

Think it’s high time you get your roof replaced? Let’s get you up to speed on everything there is to know. 🧐🏢

Understanding Commercial Roofing

Commercial roofing is distinct in its structural requirements, materials, and installation processes. Typically, these roofs are flat or have a low slope, demanding specific materials to ensure durability and weather resistance.

Your commercial roof isn’t just a shelter; it’s a strategic asset that plays a pivotal role in the building’s energy efficiency, interior comfort, and overall structural integrity. Knowing the intricacies and options available in commercial roofing is paramount to making informed decisions. 🤓📚

Materials like TPO (thermoplastic olefin), EPDM (ethylene propylene diene monomer), and modified bitumen are popular commercially for their proven resilience, longevity, and adaptability to various climatic conditions.

Every material has its unique benefits and considerations, so choosing the right one aligns with your specific needs, location, and budget. 🏭💰

The Process of Commercial Roof Replacement

Embarking on a commercial roof replacement journey isn’t an everyday affair. It’s a significant project that requires adequate preparation, the right professionals, and an understanding of the steps involved.

But don’t fret; you’re not alone in this, and having a clear roadmap can turn a seemingly daunting task into a manageable and rewarding experience. 👷♂️🗺️

What to Expect

Expect the unexpected? Not here. In a commercial roof replacement, everything is laid out. The initial phase involves a thorough inspection to assess the existing roof’s condition.

Experts will identify the level of wear, any damages, and the specific areas that need attention. This phase is critical in planning as it informs the extent of the replacement and the materials required. 🕵️♂️🔍

Safety is paramount, so measures will be implemented to protect everyone on the site, including your property. Scaffolding, safety nets, or guardrails are installed to ensure a secure working environment.

As a significant investment, expect professionalism where quality is not compromised, and every detail, from materials to installation techniques, is tailored to offer a lasting solution. 👷♀️🛠️

Timeframe

The timeframe for a commercial roof replacement can vary widely depending on the project’s size, complexity, and unforeseen challenges that might arise during the process. Weather conditions also play a significant role; favorable weather can expedite the process, while inclement weather can lead to delays. ⏳🌦️

Generally, a small to medium-sized project might take a few weeks, while larger or more complex replacements can extend to a few months. The key here is patience and understanding that quality and safety must be completed on time.

Every step, from removing the old roofing material, preparing the surface, and installing the new roof, is executed precisely to ensure your new roof stands the test of time, weather, and other potential challenges. ⏲️🏢

You’re well-equipped to make informed decisions with a clear understanding of commercial roofing and the replacement process. Remember, a well-executed commercial roof replacement enhances the building’s aesthetics, value, energy efficiency, and structural integrity.

It’s a strategic investment that yields returns in safety, reduced maintenance costs, and peace of mind knowing that you’re covered! 😉👍

Disruptions to Building Occupants

Getting a new roof is exciting, but let’s face it; it’s not exactly a silent job. There might be some noise, and a bit of coming and going of the roofing crew. It’s all in the spirit of improvement.

During a roof replacement, disruptions to building occupants are anticipated but can be managed effectively. To minimize disturbances, contractors are skilled at scheduling work in phases or during off-peak hours. Advance notification to occupants about the expected noise and temporary inconveniences aids in preparation and adjustment. 🔊🏢

To minimize interruptions, the contractors may also establish clear paths for moving materials and equipment. Encouraging occupants to voice their concerns ensures that their needs are considered throughout the project, making the process smoother.

Communication is vital, keeping everyone informed of the ongoing activities and anticipated completion timelines can alleviate anxieties and enhance cooperation. 🤝🚧

Cleanliness and Noise Considerations

Cleanliness and noise are two essential aspects managed meticulously during the process. Nobody wants debris lying around or excessive noise disrupting the daily routine. Contractors usually set up designated debris disposal areas to keep the site tidy.

Noise levels are monitored, and efforts are made to mitigate excessive noise, ensuring that while your building gets a facelift, the peace and productivity of its occupants aren’t heavily compromised. 🚮🔇

The Benefits of a New Commercial Roof

Let’s get to the sunny side of things! A new commercial roof is a gem.

It boosts the aesthetic appeal of your building, making it a sight to behold. But it’s more than a beauty upgrade; the energy efficiency game is also upped. With modern roofing technologies, expect better insulation, leading to reduced energy bills. That’s music to any business owner’s ears!

Safety and structural integrity are heightened, and maintenance headaches? Well, they take a back seat for a while. 🌟🏢

Considerations for Choosing a Commercial Roofing Contractor

Here’s where the rubber meets the road. Choosing a contractor is a critical step. Look out for experience, licensing, and insurance. Check out their previous projects, reviews, and ratings. Quality of work, professionalism, and adherence to safety standards are non-negotiable.

Your contractor should be adept at not just installing a roof but offering a seamless, hassle-free experience that leaves your building, and by extension, your business, better than they found it. 🕵️♂️👷♀️

Elevate Your Business with Alamo Roofing

A reliable partner in commercial roofing can make the journey from a weathered, aging roof to a modern, efficient, and aesthetic roofing system a walk in the park. We take pride in being that partner for businesses looking to elevate their premises without the stresses typically associated with major renovations.

When you choose us, you’re opting for quality, efficiency, and a dedicated team that views your satisfaction as the benchmark of our success. Let’s make your commercial roofing replacement journey a story of excellence, timely execution, and absolute satisfaction. 🤝🏢

by Frank Dixon | May 22, 2023 | Blog, Commercial Roof Damage, Commercial Roof Repair, Commercial roofing, Portage

Many of us are familiar with Murphy’s Law, which states that if anything can go wrong, it will go wrong. But did you know there are other “laws” as well? For example, this is Murphy’s Sixth Law: “If you perceive that there are four possible ways in which a procedure can go wrong, and circumvent these, then a fifth way, unprepared for, will promptly develop.”

Therefore, we are going to look at five of the most common causes of commercial roofing failures, be prepared for each one, and not be too surprised if something goes wrong. By preparing, perhaps these five just won’t happen.

Lack of Maintenance

This is a common reason for commercial roofs to fail. We tend to have a “replace it and forget it” approach to a roofing system. Also, we tend to believe that if we can’t see it, then it must be working. However, without proper regular maintenance, we won’t know if there are clogs in the drainage system, scratches, and dents in the roof surface, or areas of damage that have become compromised. Be sure to do yearly inspections and fix any areas that could become future problems.

Poor Installation

Place your trust in a worthy professional commercial roofing contractor in Portage when it is time to repair, inspect, or replace your roofing system. By using the least expensive option, you may have to pay more in the long run for repairs. However, using the most expensive contractor could be money wasted as well. Be sure to ask for references when you are considering a roofing contractor, and learn from your friends, family, and neighbors just who this company is, and what they stand for. After all, it’s your building and your money. Protect them both wisely.

Improper Materials

Just as the contractor is important to screen, be sure to know the proper type of roofing material you need for your building. Using the wrong materials could create issues down the road. For example, restaurants should have a roofing system that can withstand animal fats and grease. The wrong system could break down as the years of cooking and exhaust continue. Have a question-filled conversation with the roofing contractor you are considering using. They should be able to properly provide the answers you need when considering a roofing material.

Standing Water

Be sure your roofing system has proper drainage. If the slope isn’t steep enough, the water will just puddle and weaken the roof. Also, if the gutter system is clogged, the water cannot flow freely which will also create complications. Before too long, animals could find a comfy home on your flat roof if there is water available.

Punctures

Is the roofing surface walked on regularly? If so, then there could be areas of puncture. Make sure to have a strong enough surface if this will be the case. A thin weak roofing material could puncture easily and more complications can occur. Especially if regular maintenance (see above) is avoided.

Be sure to place your full confidence in a roofing contractor who will make sure these steps are secure and prepared for what may come their way. It takes a team effort to keep a roof ready to face the elements and keep the building contents protected. Alamo Roofing Contractors in Portage has your best interest at heart. We are a reputable, reliable roofing contractor ready to assist with your commercial roofing needs, and keeping Murphy, and his laws, far from you.

Give us a call today and let’s discuss your commercial roofing project!

by Frank Dixon | Jul 21, 2022 | Blog, Commercial roofing, Portage

A functional roof is integral to running a functional business. From retail buildings to industrial complexes your Portage property needs a roof that will keep your business up and running. But how do you know which commercial roofing system is best for your needs?

Image via sprayfoamaustin.net

Spray Foam Roofing

Spray foam roofing, as the name would suggest, is sprayed onto the roof and expands into the shape of the roof making it a cost-effective and versatile solution, especially for complex roofs.

Advantages

- Spray foam is very easy to install and can typically be applied with zero interruption to the daily function of the property.

- Can be applied directly over the existing roof and expand to fit all shapes and types of roofs.

- Spray foam is energy efficient, keeping cooling costs low by keeping summer heat out and holding the cold, Portage winters at bay.

- Spray foam roofs are very low maintenance.

- When appropriately applied, spray foam roofs are completely waterproof.

Disadvantages

- Improperly applied spray foam doesn’t work and can even damage the property – installers need to have high technical knowledge.

- The weather conditions must be appropriate for spray foam installation which can be trickly with the volatile weather in Portage.

- While generally low-maintenance, spray foam roofs should be inspected at least twice a year to ensure they haven’t been damaged.

- Damaged spray foam can be finicky to repair.

Modified Bitumen Roofing

Modified bitumen roofing is an asphalt-based roofing system that is designed to withstand harsh exposure and environments. It was created for low-slope and flat roof structures.

Advantages

- Modified bitumen roofing is tear resistant due to its reinforcement layers.

- Modified bitumen roofing is extremely waterproof, preventing leaks even in the sometimes extreme weathers in Portage.

- Adding a cool roof like solar reflection to the top layer of your modified bitumen roof can help it to be energy efficient.

- Due to its flexibility, modified bitumen expands and contracts with temperature changes.

- Repairs and maintenance are very easy.

Disadvantages

- Older modified bitumen roofing installation processes can be a fire hazard due to the need for heated installation.

- Modified bitumen roofing can be fragile when disturbed and isn’t suitable for areas of high foot traffic.

- The impact resistance of modified bitumen isn’t as high as other commercial roofing materials.

- The life expectancy of modified bitumen roofing is somewhat short at 10-20 years.

- EPDM is an energy efficient commercial roofing option that can help keep out heat in the summer and keep in heat in the winter.

EPDM Roofing

EPDM roofs have a thin, waterproof rubber membrane that’s both durable and easy to install.

Advantages

- EPDM roofing is extremely cost effective and less expensive than other commercial roofing options.

- Made from 100% recyclable materials, EPDM roofs are very eco-friendly.

- EPDM roofs are very fire resistant.

- Properly installed and maintained EPDM roofs can last 20+ years.

Disadvantages

- While it’s an overall inexpensive roofing option, more technical EPDM installations can be costly depending on the specific choices you make.

- Non-reinforced EPDM is prone to puncturing and shrinkage which can lower its lifespan.

- EPDM roofs are somewhat unattractive.

TPO Roofing

TPO roofs are a single-ply membrane used to protect from leaks and is considered a green option due to its heat reflective properties.

Advantages

- TPO roofing is a very durable option for a low slope roof system with a strong resistance to tears and punctures.

- Due to its water resistance, TPO is fungi resistant.

- TPO comes in a variety of color options which can help with both UV resistance and aesthetic appeal.

- TPO roofs have a high impact resistance rating making them perfect for areas like Portage that are prone to hail.

- TPO roofs have an expected lifespan of 20-30 years, are easy to install, and are low maintenance.

Disadvantages

- Not all brands of TPO are created equal, and it’s a relatively new product having only been introduced in the last 30 years, so quality can be hit or miss.

- The cost for a TPO roof in Portage is higher than that of other commercial roofing options, but its durability and lifespan make up for the higher price tag.

- TPO isn’t inherently fire resistant, although it can have fire retardant added.

- Repairs require special tools like a heat welder, so, typically, TPO roofs can only be repaired by a professional.

How To Choose the Best Commercial Roof For Your Portage Property

When its time to install or replace your commercial roof in Portage you’ll want to work to strike the perfect balance for your property. Some of the things you’ll need to consider are:

- Energy Efficiency

- Budget

- Pitch of the Roof

- Aesthetic Needs

- Longevity and Durability

- Local Climate

Alamo Roofing Contractors is your leading commercial roof contractor in Portage. Call us today to schedule your free estimate and discuss your options!